This machine is designed for the sole purpose of running 1” flush wall panels 10” to 20” finished width.

Unlike the previous two units this machine is designed for the sole purpose of running 1” Flush wall panels 10” to 20” finished width.

Optional items are pretty much the same, with the 12,000 lb capacity NATM compliant tandem axle trailer, the machine mount dual overhead reel rack (as seen in the picture above), a 16” ID or a 20”ID decoiler reel, or the 16” to 20” expandable arbor ( as seen in the picture above), 10’ sections of variable height run out table, powered perforator w/ 2 sets of perforated rollers.

The quick change power pac feature allows you to change from a 7.5 hp, 220vac, 60hz, 3ph, 18amp electric motor to a 5hp, 220vac, 50or 60 hz, 1ph, 30amp electric motor or a 16hp Briggs and Stratton electric start engine.

Features

- Separate Polyurethane Drive Rollers

- Hardened Stainless Steel Forming Roller System with Shear Dies

- Quick Change Power PacTM, Gas or Electric

- Power Interruption Safety Circuit

- Hydraulic Drive and Shear

- Length Control Limit Switch

- One Pair of Bead, Pencil, or V Rib Rollers

- Push Button RUN/JOG Controls at Entry and

- Exit Ends

- Welded Tubular Steel Frame

- Underdeck Attachment

- Industry’s Best Warranty

Specifications

FWM Panel machine

Length 12’ 10” (3.9m)

Width 3’10” (1.2m)

Height 4’3” (1.3m) w/ Over Head Rack

2’0” (.6m) w/o Over Head Rack

Weight 2200 lbs. (1000kg)

FWM On Trailer

Length 17’6” (5.3m)

Width 7’ (2.1m)

Height 6’3” (1.9m) with reel

Weight 3800 lbs. (1700kg)

Speed

60 ft/min (18m/min) Approx.

Drive

Hydraulically Driven Polyurethane Rollers

Shear

Hydraulically Powered, Infinitely Adjustable,

Hardened Tool Steel Blades and Dies

Panel Recognition Safety Photo Eye

Coil Width

14” to 24” (350mm to 600mm)

Materials Formed

Steel 30 ga. to 24 ga. (.3mm to .6mm)

(painted, galvanized, aluminized)

Painted Aluminum .019” to .040” (.5mm to 1.0mm)

Copper 16 oz. to 20 oz. 3/4 Hard

(.5mm to .7mm)

Bench Brake – 2 ft. and 4 ft.

Brakes, Sheet Metal Equipment

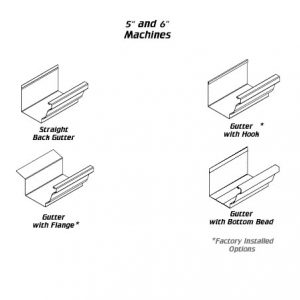

Mach II Gutter Machines – 5 in, 6 in, and Combo

Gutter & Downspout, Sheet Metal Equipment

Standard Pittsburgh Machine

Gutter & Downspout, Sheet Metal Equipment